Nano Titanium Oxide - Arsenic & Heavy Metal Reduction Media - 1 cu.ft Bag ~40 Lbs.

- NTO media reduces arsenic III and V plus a wide variety of heavy metals and other contaminants including Lead, Cadmium, Copper, Chromium+6 , Selenium, Uranium, Antimony and Zinc.

- Standard replacement media for WECO NTO whole house arsenic removal filters.

- 1 ft³ Bags. 40 lbs. per ft³.

- Typically configured with a gravel base and 4-6" filter sand layer.

- Sold in full bags only.

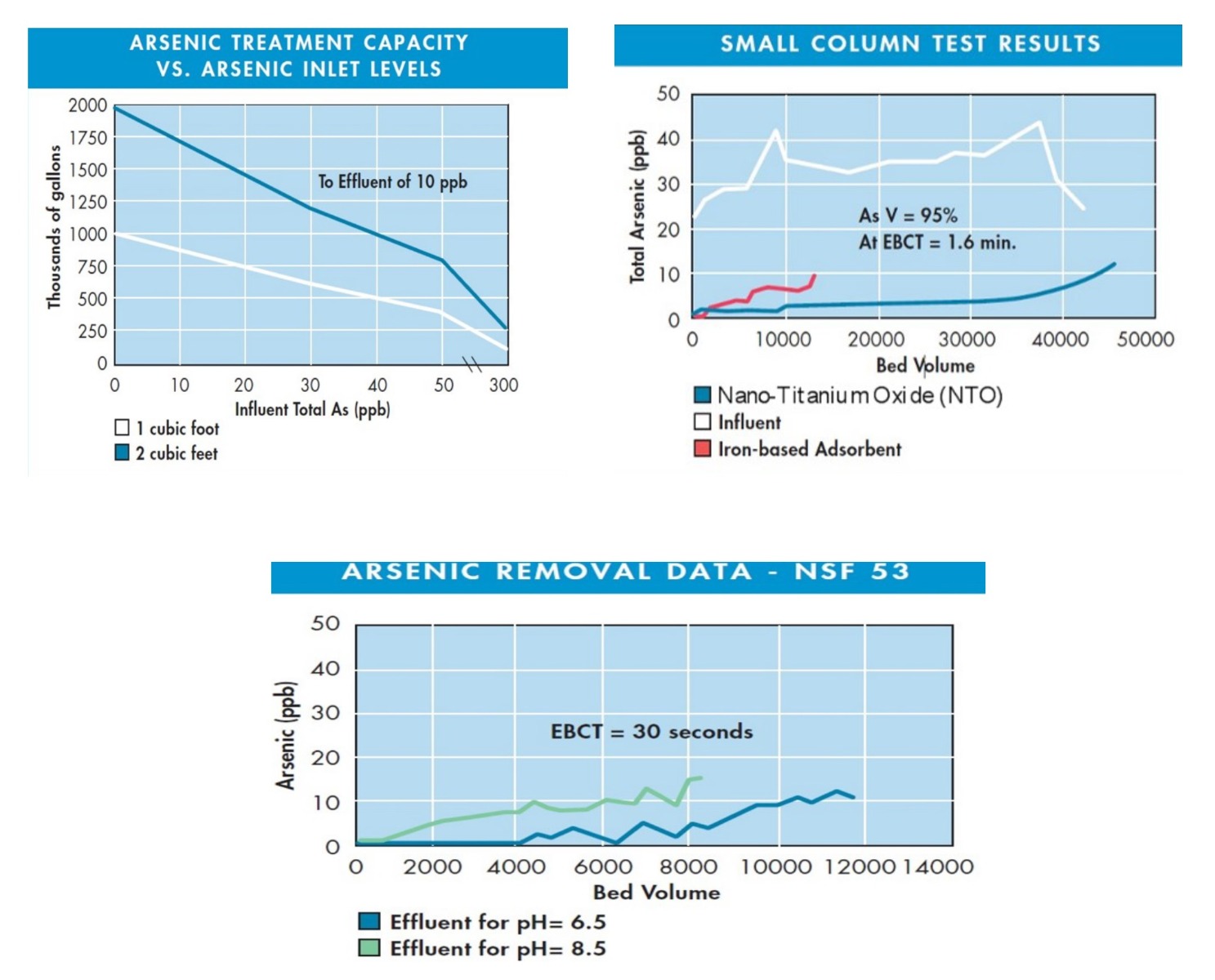

The current drinking water standard or Maximum Contaminant Level (MCL) set by the U.S. Environmental Protection Agency (EPA) for Arsenic is 0.010 mg/L or parts per million (ppm). This is equivalent to 10 ug/L (micrograms per liter) or 10 ppb. In 2001, the U.S. Environmental Protection Agency (EPA) reduced the regulatory MCL from 50 ppb to 10 ppb on the basis of bladder and lung cancer risks.

Nano-Titanium Oxide (NTO) is a USA made, highly effective granular adsorbent media. Properly applied, NTO media reduces arsenic III and V plus a wide variety of heavy metals and other contaminants including Lead, Cadmium, Copper, Chromium+6 , Selenium, Uranium, Antimony and Zinc. Empty bed contact times as low as 10 seconds will achieve significant removal efficiencies. NTO affords a higher capacity and lower level of ion interference than competitive iron and alumina based products. NTO’s adsorptive capacity will vary with the solution concentration of contaminant. NTO has an excellent adsorbent capacity resulting from the high surface area and large pore volumes. Reduced change-out frequency and fast kinetics allow for less media volume and a smaller equipment footprint. NTO also pass-es EPA toxicity characteristic leach procedure (TCLP) and the CA WET (California Waste Extraction Test) so it may be disposed of as Non-Hazardous Solid Waste. (Local codes and ordinances must be followed).

When an iron reduction system is installed ahead of an arsenic reduction system, Katalox Light® is the pre-ferred choice as it will help convert trivalent arsenic to pentavalent arsenic to enhance removal at subsequent treatment steps. Where the iron level is at least 20 times the arsenic level, indirect removal of arsenic is likely through adsorption to the ferric hydroxide parti-cles created during iron removal (co-precipitation), so a dedicated arsenic filter may not require a redundant unit. Follow-up testing should be done to confirm satis-factory arsenic reduction across both units.

Operational Design Parameters

| Service Flow | EBCT | Min. Bed Depth | Backwash Rate | Recommended Freeboard | Under-bedding | Iron and Manganese | Sediment | Hardness | pH | Oxidants |

|---|---|---|---|---|---|---|---|---|---|---|

| ≈5-10 gpm ft² | ≈1.5-3 minutes | 24” | ≈4-5 gpm ft² | 50% | Gravel and sand highly recommended | Reduce iron to <0.3ppm and manganese to <0.05ppm | Pre-treat system with a 25μ or smaller filtration | Hardness is beneficial to NTO, install softeners after if needed | pH levels should be below 8.2 for effective and satisfactory media performance | Oxidants need to be removed prior to NTO |

| UPC | 032733544803 |

|---|