Katalox Light® Advanced Filtration Media for Iron, Manganese and Hydrogen Sulfide Removal

- High content MnO2 coating (10%)

- Very High Surface Area

- Contains NO Crystalline Silica

- Light Weight - providing significant savings on backwash water

- Higher Filtration rates

- Filtration of sand, sediment and suspended solids, down to 3 micron

- High efficiency removal capacity of Iron,

- Manganese and Hydrogen sulfide

- Effective reduction of Arsenic, Zinc,

- Copper, Lead, Radium, Uranium, radionuclides and other heavy metals

- Media replacement every 7 - 10 years

- No disinfection by-product

- No mandatory KMnO4, chlorine or chlorine dioxide dosing

- Low operational costs

Advanced Filtration Media

Filtration of

Removal of

What is Katalox Light®?

Katalox Light® is a new brand of revolutionary advanced filtration media completely developed in Germany. It's composition simply makes it outstanding against the contemporary filter media available in water treatment industries, like sand, BIRM, Greensand Plus, Manganese Greensand etc. Katalox Light® is manufactured in Germany.

Katalox Light® is engineered with unique MnO2 coating technique on ZEOSORB®, providing it light weight, higher filtration surface, more service life and more reliable performance (filtration down to 3μm) than any other existing granular filter media.

Katalox Light® is being used in numerous system for residential, commercial, industrial and municipal applications worldwide, for High level filtration, color and odor removal, Iron, Manganese, Hydrogen sulfide removal, efficient reduction of Arsenic, Zinc, Copper, Lead, Radium, Uranium and other radionuclides and heavy metals.

Katalox Light® is ANSI/NSF 61 Certified for drinking water applications and has met the ANSI/NSF 372 Lead free compliance.

Advanced use

High concentration coating of MnO2 on the Katalox Light® surface (10%) is the biggest advantage compared to any similar product available in the market. This makes the oxidation and co-precipitation of contaminants much more effective. For removal of very high concentration of contaminant it's recommended to use H2O2 as an oxidizer, which provides accelerated catalytic oxidation on the surface of the media. Conventional oxidizing agents like chlorine or potassium permanganate also could be used if required.

Katalox Light® can be used for Arsenic, Radium, Uranium removal but in these cases there is requirement of Iron in the water. Katalox Light® system is designed with special iron dosing technology which has many advantages over Adsorbent media used for Heavy Metal removal.

ADVANTAGES:

The Future

The future of water treatment, as we see it, is going to give us more difficult challenges and we all need more advanced and robust products.

In Watch®'s vision, Katalox Light® can be addressed for advanced concepts like Water Reuse, Controlled Adsorption of Arsenic and Heavy Metals, advanced Membrane pretreatment, Zero-Discharge Cooling tower etc.

Contact us for information.

Standard Packaging:

1 ft³ bags (28 Liters); Mass: 30 kg (66 lb)

40 bags on a Pallet

16 Pallets in a container

Katalox Light Systems

Watch® Katalox Light® systems offer a new technology with advanced catalytic filtration available in water treatment industry. All systems have been engineered keeping both professionals and consumers in mind. Systems are available with diff erent models and customized for manual backwash without using electricity or it can be made fully-automatic. System can be used in a variety of applications including residential, commercial and any process water applications for food and beverage industry.

Standard systems are designed with a filtration velocity of 20 m/h (8.2 gpm/ft2) to provide a good filtration. This value may differ for advanced application like Arsenic, Radium, Uranium and other Heavy Metal removal where co-precipitation process requires higher contact time thus lower filtration velocity. Running the system at higher velocity may compromise the filtration performance.

Virtually there is no flow rate limitations for KL systems as KL units can be configured in parallel to address industrial high flow requirements.

KL System with simple Manual Control

KL System with fully Automatic Control

Parallel configuration for Higher Flow rates

Example:

2 parallel KL 1465-Mn would have a total flow of 2 x 3000 lph = 6000 lph (26.2 gpm)

Standard Pressure Vessel Listing for KL Systems (Manual/Automatic)

| Pressure Vessel | KL media amount | Service flow rate | Backwash | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| volume | Bed Height | Standard | Maximum | ||||||||

| Vessel Model | Area | Freeboard | flow-rate | flow-rate | flow-rate | ||||||

| m2 | % | liters | ft3 | mm | m3/h | gpm | m3/h | gpm | m3/h | gpm | |

| 08x44 | 0.03 | 30 | 24 | 0.8 | 725.3 | 0.6 | 2.9 | 1.0 | 4.3 | 0.8 | 3.6 |

| 10x54 | 0.05 | 30 | 42 | 1.5 | 838.6 | 1.0 | 4.5 | 1.5 | 6.7 | 1.3 | 5.6 |

| 12x52 | 0.07 | 30 | 56 | 2.0 | 767.5 | 1.5 | 6.4 | 2.2 | 9.6 | 1.8 | 8.0 |

| 14x65 | 0.10 | 30 | 98 | 3.5 | 986.8 | 2.0 | 8.7 | 3.0 | 13.1 | 2.5 | 10.9 |

| 16x65 | 0.13 | 30 | 126 | 4.5 | 971.3 | 2.5 | 11.4 | 3.9 | 17.1 | 3.2 | 14.3 |

| 18x65 | 0.16 | 30 | 170 | 6.0 | 1035.5 | 3.5 | 15.5 | 4.9 | 21.7 | 4.1 | 18.1 |

| 21x60 | 0.22 | 30 | 224 | 8.0 | 1002.4 | 4.5 | 19.7 | 6.7 | 29.5 | 5.6 | 24.6 |

| 24x69 | 0.29 | 30 | 308 | 11.0 | 1055.3 | 6.0 | 26.3 | 8.8 | 38.6 | 7.3 | 32.1 |

| 30x72 | 0.46 | 30 | 510 | 18.0 | 1118.3 | 10.0 | 44.2 | 13.7 | 60.2 | 11.4 | 50.2 |

| 36x72 | 0.66 | 30 | 764 | 27.0 | 1163.4 | 15.0 | 66.0 | 19.7 | 86.7 | 16.4 | 72.3 |

| 42x78 | 0.89 | 30 | 935 | 33.0 | 1046.1 | 20.0 | 86.6 | 86.6 | 118.1 | 22.3 | 98.4 |

| 48x82 | 1.17 | 30 | 1300 | 46.0 | 1113.5 | 25.0 | 110.0 | 35.0 | 154.2 | 29.2 | 128.5 |

Technical Data

Composition of KATALOX LIGHT®:

| Compounds | Typical value | Specifications |

|---|---|---|

| ZEOSORB (Naturally Mined) | 85% | >85% |

| Manganese dioxide | 10% | >9.5% |

| Hydrated Lime | 5% | >5% |

Physical Properties:

| Appearance | Granular black beads | ||

| Odor | none | ||

| Mesh size | US | 14 x 30 | |

| SI | 0.6 - 1.4 mm | ||

| Uniformity Coefficient | ≤ 1.75 | ||

| Bulk density | US | 66 lb/ft3 | |

| SI | 1060 kg/m3 | ||

| Moisture Content | <0.5% as shipped | ||

| Filtration | <3 micron | ||

| Uniformity Coefficient | for Fe2+ alone | 3000 mg/l 85000 mg/ft3 (aprx) |

|

| for Mn2+ alone | 1500 mg/l 42500 mg/ft3 (aprx) |

||

| for H2S alone | 500 mg/l 14000 mg/ft3 (aprx) |

||

Recommended System Operating Conditions:

| Inlet water pH | 5.8 - 10.5 | ||

| Freeboard | 25 - 35% | ||

| Min. Bed Depth | US | 29.5 inches | |

| SI | 75 cm | ||

| Optimal Bed. Depth | US | 47 inches | |

| SI | 120 cm | ||

| Service flow | US | 6 - 12 gpm/ ft2 | |

| SI | 15 - 30 m/h | ||

| Backwash velocity | US | 8 - 10 gpm/ ft2 | |

| SI | 20 - 25 m/h | ||

| Backwash time | 5 -10 minutes | ||

| Rinse time | 1 - 2 minutes | ||

Regeneration/Dosing (optional*)

| *Only if the water doesn't have sufficient oxygen to oxidize the contaminants. It also helps to clean the media surface better if used at the backwash | |||

|---|---|---|---|

| H2O2 | for 1.0 mg/l of | Fe2+ | 0.9 mg/l |

| for 1.0 mg/l of | Mn2+ | 1.8 mg/l | |

| for 1.0 mg/l of | H2S | 4.5 mg/l | |

| KMnO4/CI | for 1.0 mg/l of | Fe2+ | 1.0 mg/l |

| for 1.0 mg/l of | Mn2+ | 2.0 mg/l | |

| for 1.0 mg/l of | H2S | 5.0 mg/l | |

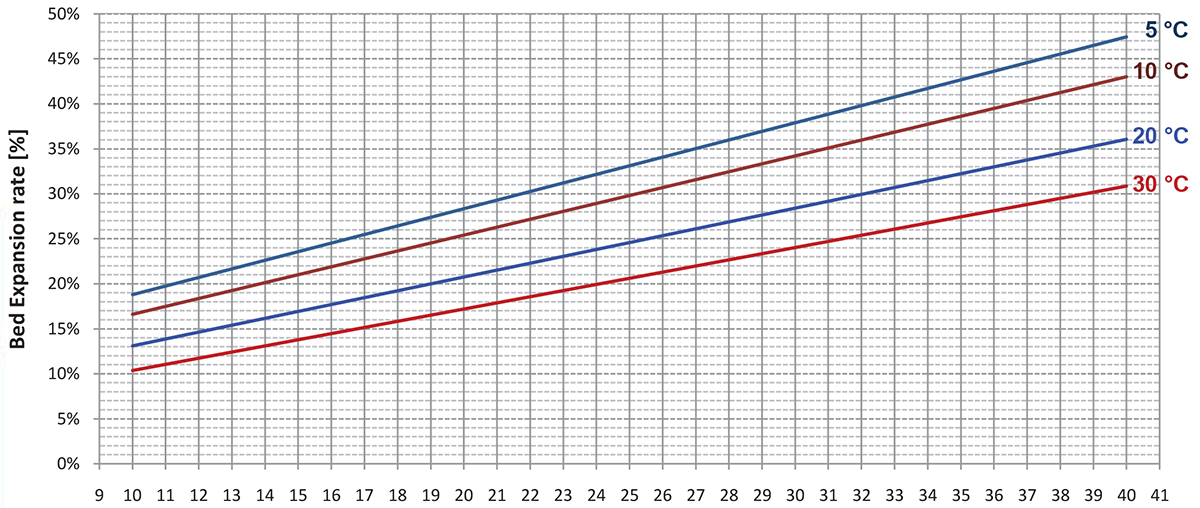

Backwash Velocity [m/h] vs. Bed Expansion [%]:

| UPC | 719284871755 |

|---|