- Mixed bed deionization (DI) resin tank with garden hose connectors.

- Functionality:

- The cation resin, typically in the hydrogen form (H+), exchanges positively charged ions (like calcium, magnesium, and sodium) for hydrogen ions.

- The anion resin, typically in the hydroxide form (OH-), exchanges negatively charged ions (like chloride, sulfate, and bicarbonate) for hydroxide ions.

- The released hydrogen ions (H+) and hydroxide ions (OH-) then combine to form pure water (H2O).

- Applications:

- Spot-free rinsing: DI water is ideal for final rinsing in applications where mineral deposits are undesirable, such as automotive detailing, electronics manufacturing, and laboratory glassware cleaning.

- Total dissolved solids (TDS) reduction: It effectively removes a wide range of dissolved salts and minerals, significantly reducing TDS levels.

- Laboratory applications: Many laboratory procedures require ultrapure water for accurate and reliable results. DI water meets the stringent purity requirements of various analytical and experimental applications.

- Industrial processes: Many industrial processes, such as boiler feed water, require high purity water to prevent scaling and corrosion.

- Reverse osmosis (RO) pre-treatment:

- Using reverse osmosis as a pre-treatment step significantly extends the lifespan and capacity of the DI resin.

- RO removes a substantial portion of the dissolved solids before the water enters the DI tank, reducing the load on the resin and increasing the volume of water that the resin can purify before needing regeneration or replacement.

- Capacity Considerations:

- The capacity of a DI resin tank is determined by the amount of ions it can remove before exhaustion.

- Factors affecting capacity include the initial TDS of the water, CO2 and the flow rate.

- Capacity estimator available in the description, allows for the estimation of the amount of water that can be treated before the resin needs to be regenerated or replaced.

- Recommended peak flow ~15 GPM.

- 6 cu.ft of deionizing resin media.

Deionization (DI) Tanks

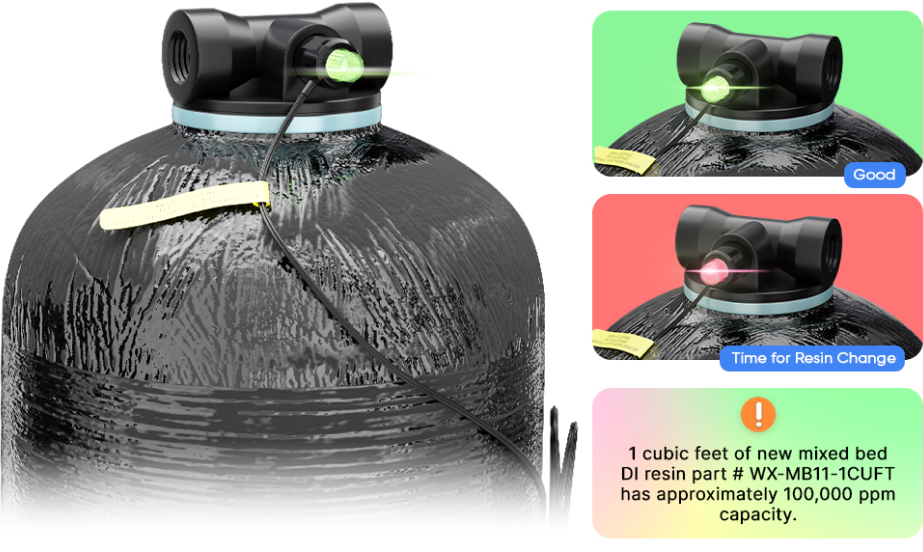

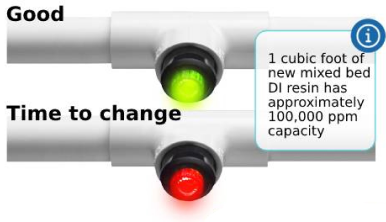

Deionization (DI) effectively removes the majority of dissolved ions and is well-suited for tasks such as RO polishing, spot-free rinsing, or any application demanding minimal dissolved solids. Custom configurations are also available. The square wave monitor presents a dependable and cost-effective method for monitoring water quality via conductivity.The easily discernible bright red or green visual display simplifies monitoring.

The system is straightforward: a green light signals that water conductivity is below the threshold value, while a red light serves as a warning if it surpasses this level. The solid-state circuitry employs a symmetrical square wave sampling voltage to prevent plating and extend the electrode's lifespan.

The LED output and solid-state circuitry have a significantly longer lifespan compared to conventional neon lamps, lasting for thousands of hours. The monitor utilizes a wall transformer to convert 120 VAC into 9 VDC, ensuring both safer operation and an extended operational life. The LED Indicator Resistivity Monitor maintains an accuracy level of ±15%. Each system includes a 110V wall power supply with a 9-foot cord for added convenience.

Standard Features

Spot Free Rinsing

DI water prevents unsightly water spots on vehicle surfaces, as it lacks mineral deposits, ensures a streak-free and pristine finish.

Window Cleaning

Using DI water for window cleaning gets you streak-free, crystal-clear results by eliminating mineral deposits and ensuring a spotless shine.

Wash Solar Panels

Rinsing solar panels with deionized water maximizes energy efficiency by preventing mineral buildup, ensuring optimal sunlight absorption.

Aquarium Water

DI water is vital for aquariums, as its purity ensures a safe and pristine environment for aquatic life, free from harmful contaminants.

Pilot Testing Boiler App-s

Utilizing DI water for pilot testing boiler feed water assures accurate results by eliminating impurities, ensuring optimal boiler performance.

Semiconductor Industry

In the semiconductor industry, DI water's ultra-purity is essential, as it prevents contaminants, ensuring flawless chip manufacturing processes.

High Purity Lab-ry Water

DI water is indispensable in laboratories, offering unmatched purity for precise experiments, chemical analyses, and maintaining equipment integrity.

Steam Iron Water

DI water is a must for steam irons and humidifiers, preventing mineral buildup, ensuring longevity, and delivering efficient performance.

DI Systems

| Model# | Mineral Tank Size |

Recommended Peak Flow |

Media Ft3 |

|---|---|---|---|

| DIBP-0918 | 9" x 18" | ~2 GPM | 0.4 |

| DIBP-1018 | 10" x 18" | ~3 GPM | 0.5 |

| DIBP-0844 | 8" x 44" | ~4 GPM | 1 |

| DIBP-0948 | 9" x 48" | ~5 GPM | 1.5 |

| DIBP-1054 | 10" x 54" | ~6 GPM | 2 |

| DIBP-1252 | 12" x 52" | ~8 GPM | 3 |

| DIBP-1354 | 13" x 54" | ~10 GPM | 3.5 |

| DIBP-1465 | 14" x 65" | ~12 GPM | 5 |

| DIBP-1653 | 16" x 53" | ~12 GPM | 5 |

| DIBP-1665 | 16" x 65" | ~15 GPM | 6 |

Add a connector set, see the Clack install part page for options

DI Systems with Resistivity Monitor

| Model# | Mineral Tank Size |

Recommended Peak Flow |

Media Ft3 |

|---|---|---|---|

| DIBRS-0918 | 9" x 18" | ~2 GPM | 0.4 |

| DIBRS-1018 | 10" x 18" | ~3 GPM | 0.5 |

| DIBRS-0844 | 8" x 44" | ~4 GPM | 1 |

| DIBRS-0948 | 9" x 48" | ~5 GPM | 1.5 |

| DIBRS-1054 | 10" x 54" | ~6 GPM | 2 |

| DIBRS-1252 | 12" x 52" | ~8 GPM | 3 |

| DIBRS-1354 | 13" x 54" | ~10 GPM | 3.5 |

| DIBRS-1465 | 14" x 65" | ~12 GPM | 5 |

| DIBRS-1653 | 16" X 53" | ~12 GPM | 5 |

| DIBRS-1665 | 16" X 65" | ~15 GPM | 6 |

Many other sizes available

Resistivity Monitor Components

| Item# | 1/2" Monitor |

|---|---|

| 39L-R73020 | 20K Ohm(~24 ppm) |

| 39L-R73050 | 50K Ohm(~10 ppm) |

| 39L-R73200 | 1 200K Ohm(~1 ppm) |

| 39L-R73500 | 500K Ohm(~1 ppm) |

| 39L-R3M | 1 Meg Ohm(~.5 ppm) |

| Item# | 3/4" Monitor |

| 39L-R74020 | 20K Ohm(~24 ppm) |

| 39L-R74050 | 50K Ohm(~10 ppm) |

| 39L-R74200 | 200K Ohm(~1 ppm) |

| 39L-R74500 | 500K Ohm(~1 ppm) |

| 39L-R4M | 1 Meg Ohm(~.5 ppm) |

| Item# | Accessories |

| 39L-7009 | 2 Monitor In/Out head,uses 1/2" Monitor. 3/4 FNPT 13/16 riser |

| 55H-402-005G | 1/2" PVC Tee for 1/2 Monitor |

| 55H-402-101G | 3/4" PVC Tee for 1/2 Monitor |

| 55H-402-131G | 3 1" PVC Tee for 1/2 Monitor |

| Resistivity(ohm-cm) | Conductivity(uS-cm) | ~TDS+15%(ppm) | Max/MinpH |

|---|---|---|---|

| 18 MEG | 0.056 | .028 | 7.8/6.2 |

| 14 MEG | 0.071 | .036 | 7.9/6.1 |

| 10 MEG | 0.1 | .5 | 8.1/5.9 |

| 6 MEG | 0.167 | .083 | 8.3/5.7 |

| 2 MEG | 0.5 | .25 | 8.8/5.2 |

| 1 MEG | 1 | .50 | 9.1/4.9 |

| 500K | 2 | 1 | 9.4/4.6 |

| 200K | 5 | 2.5 | 9.8/4.2 |

| 50K | 20 | 10 | 10.4/3.6 |

| 20K | 50 | 24 | 10.9/3.2 |

| 10K | 100 | 48 | 11.2/2.9 |

| 5K | 200 | 95 | 11.3/2.6 |

| 1K | 1000 | 500 | 12.2/1.9 |

Wall Power Supply

A 9-foot-long wall power supply ensures secure low-voltage power delivery to the resistivity monitor, guaranteeing safety and reliability.

LED Light Conductivity Monitor

The bright red or green LED is easy to read. Green light for conductivity below threshold, red for above, making monitoring simple.

NPT Threaded Ports

Crafted from durable ABS plastic, the standard 3/4" NPT female threaded port head features monitor electrodes positioned at the outlet.

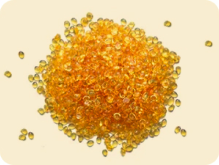

Quality Mixed Bed DI Resin

WX-MB11-1CUFT mixed bed DI resin combines both cation and anion resins in a single container, efficiently producing pure water by removing all ions.

Technical Specifications

Resistivity Monitor500 K ohm/cm (2 mho/cm) Accuracy ± 15%

Port Size3⁄4” NPT

Electrode MaterialTungsten

Voltage120V Supply & 9 VDC Output with 200 mA Current (Typical DC Current 35 mA)

Maximum Temperature100 °F

Cord Length9 feet