WECO CALC-1054 Backwashing Filter with Calcite and Magnesia for pH Neutralization

- Proprietary blend of natural crushed and screened white marble calcite media combined with processed hard bead magnesia neutralizes acidic water and raise the pH.

- Automated backwashing valve, calcite distributor and support bedding prevents cementing of media, reclassifies the bed and restores high service flow rates.

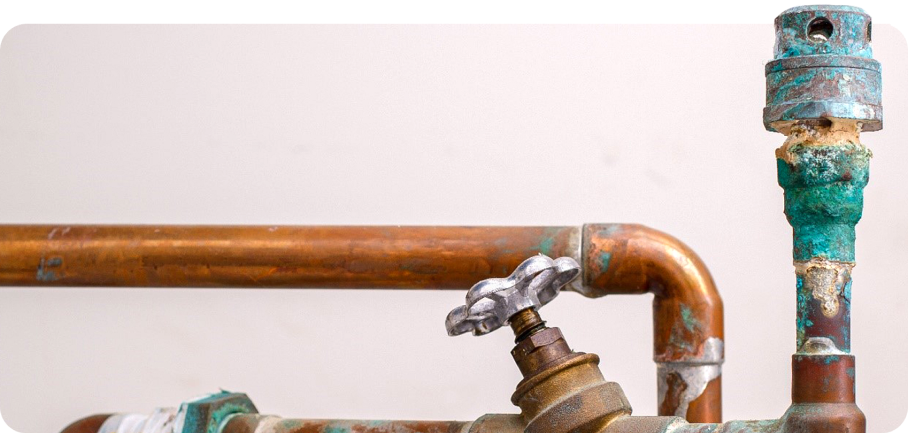

- Prevents damage to plumbing, boilers and manufacturing equipment.

- Stops lead, copper and iron leaching from pipes and solder due to low water pH.

- Eliminates blue, green and red stains in sinks, tubs and showers.

- Improves water clarity, removes tubidity.

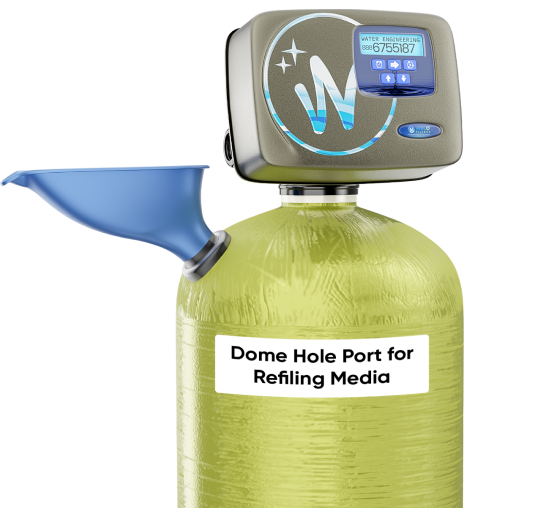

- Dome hole, included funnel and natural color-translucent tank simplifies the periodic replenishment of media.

Acidic Water Neutralizing Systems

Calcite & Corosex Media Systems

- Proprietary blend of natural crushed and screened white marble calcite media combined with processed hard bead magnesia neutralizes acidic water and raise the pH.

- Prevents damage to plumbing, boilers and manufacturing equipment.

- Stops lead, copper and iron leaching from pipes and solder due to low water pH.

- Eliminates blue, green and red stains in sinks, tubs and showers.

- Improves water clarity, removes tubidity.

- Dome hole, included funnel and natural color translucent tank simplifies the periodic replenishment of media.

& Low pH

Adjusting System

& Low pH

System + Softener(If desired)

Low pH water (<7 pH) can cause bluish green staining on plumbing fixtures and eventually cause corrosion and leaks. Depending on the pH of your water, Calcium Carbonate (CaCO3) and/or Magnesium Oxide (MgO) are commonly used for pH correction. Flow rates are key to a sucessful operation. Monitor performance to confirm proper operation. Upflow systems cost less upfront but require consitent water flow for optimum neutralizing results.

Neutalizing with calcium carbonate and/or magnesium oxide will increase water hardness. Installing a sub sequent water softener as needed. Our Proportional pH Adjusting Systems that inject soda ash to your water stream does not increase water hardness.

Contact our WQA certified water specialists with your number of bathrooms, well pump backwash flow rate for assistance in designing a system.

Easy Media Replenishment

Dome hole, included funnel and natural color-translucent tank simplifies the periodic replenishment of media.

Upflow Systems

Simple in and out filter with upflow riser configuration. Dome hole natural color tank vessel with funnel makes media replenishment easy.

| Model | Unit Dimensions | Recommended Peak Flow Rate |

| CMPUX1054 | 10 x 10 x 64 Inches | 3 GPM |

| CMPUX1354 | 13 x 13 x 64 Inches | 5.5 GPM |

Backwash Systems

Automated flow reversing valve, calcite distributor and support bedding prevents cementing of media, reclassifies the bed and restores high service flow rates.

| Model | Unit Dimensions | Recommended Peak Flow Rate | Required Backwash Flow Rate |

| CALC-1054 | 10 x 10 x 64 Inches | 3 GPM | 5 GPM |

| CALC-1354 | 13 x 13 x 64 Inches | 5.5 GPM | 9 GPM |

Proportional pH Adjusting Systems

| Model | PPH-35-FP30 |

| Flow Meter Size | 1” |

| Tank Size | 35 Gallons |

| Max Flow | 50 GPM |

Chemical Injection system automatically adjust the water pH to maintain desired pH regardless of water flow.

A sample port and a handheld digital pH meter are used to adjust the chemical pump rate to maintain the desired pH.

Ideal for most residential and many light commercial applications.

Pilot Test Units & More

Slim & Big Blue type cartridges in 10” and 20” lengths, pilot test units, cartridge tank systems and custom filter units available. Contact us for more details.

| UPC | 810388030250 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specifications |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| QA Image |  |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PDF Guide |

Control Head Installation

A300E Process Medium

Recommended Setup |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||