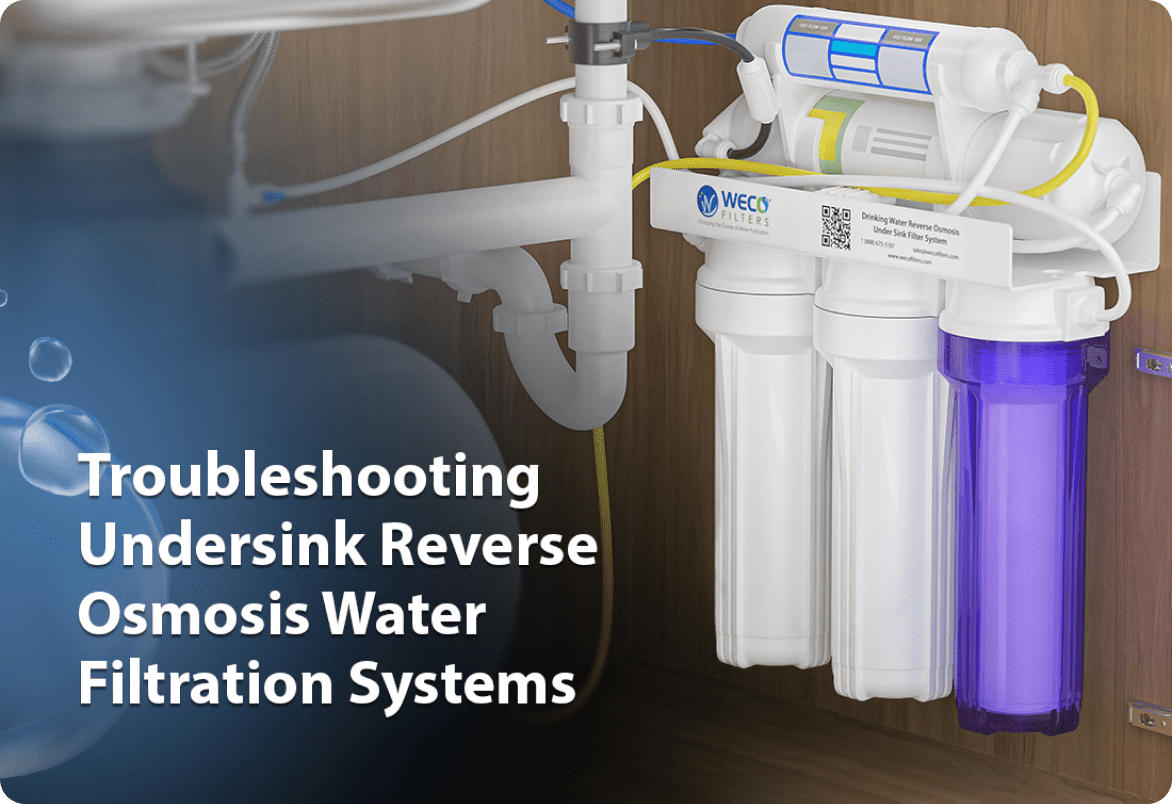

Troubleshooting Undersink Reverse Osmosis Water Filtration Systems

Insufficient water pressure or minimal flow from the RO faucet.

- The RO pressure tank is still not completely filled.

- Give it more time to reach full capacity. Typically takes about 1 hour to fill a standard 4-gallon tank under city water pressure (around ~60 PSI). If you're using well water, the filling time may be even longer.

- The membrane is clogged. Remove the drain flow restrictor, allow unrestricted water flow for 10 minutes to flush the membrane, and then reattach the restrictor.’

- If your water is very hard (exceeding 10 grains) or if the reverse osmosis membrane has been in use for more than 2 years, it is advisable to remove membrane and all other filters, sanitize the RO system and replace both the reverse osmosis membrane and all other filters. If this keeps happening frequently, resize the flow restrictor to allow more drain flow.

- RO installed in basement. - For basement RO installations with connections on upper floors for faucets, ice makers, or refrigerators, consider using a delivery pump and potentially an RO booster pump. Refer to the blog article on boosting RO water pressure for more information. https://www.wecofilters.com/blog/post/booster-pump-installation

- There are kinks in the water line. Replace the tubing or address any kinks or restrictions in the water line.

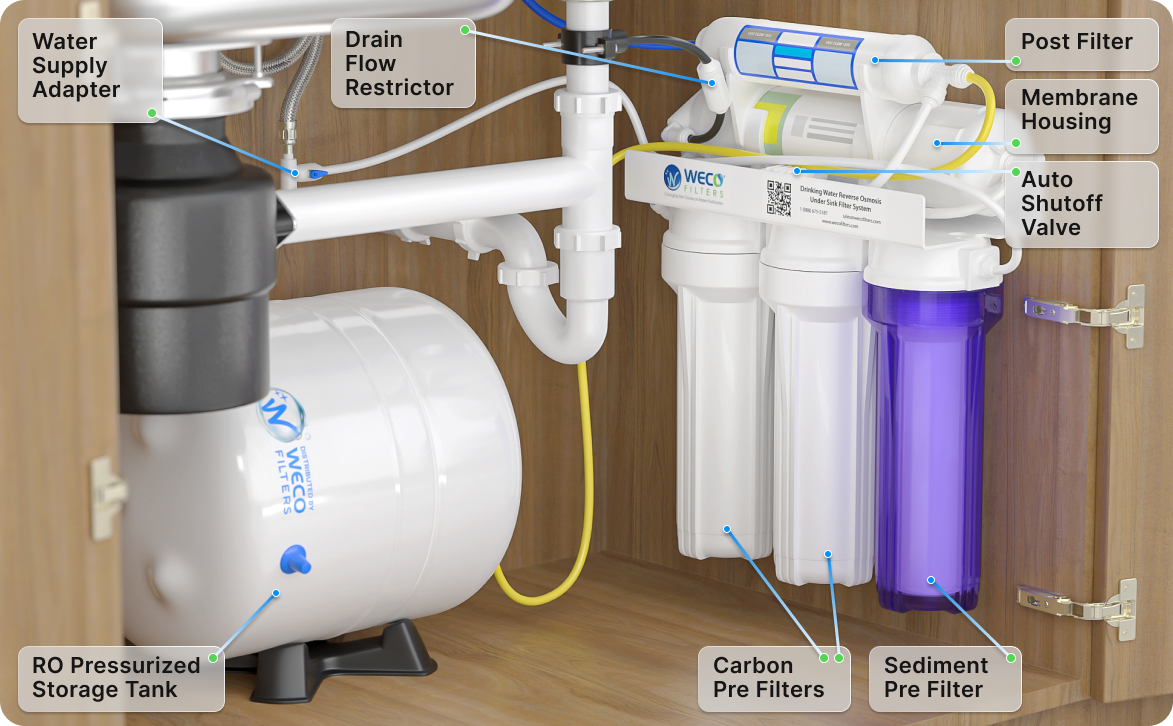

- The RO water supply adapter valve is not completely open.

- Pre or post filters clogged. Replace the filter cartridges at least every year.

- City water pressure restriction at the curb. No water pressure from faucets or showers either. Check with your water utility. If the city water pressure drops delow 20 PSI your utility will also issue a boil water advisory.

- Too many connected fixtures and RO cannot keep up. In addition to the RO faucet, you may have ice makers, refirdgerator water lines, bar faucets, coffee makers emtying the RO tank. You may want to consider a booster pump, tank upgrade, upsize tubing, membrane upgrade and/or delivery pump. Refer to boositing RO water pressure blog article. https://www.wecofilters.com/blog/post/booster-pump-installation

- RO booster pump (electrical pump systems only) not working. Check if the power supply is working. Check the electrical outlet has power. Check if the wire harness between the pump, pressure sensors and power supply is loose and fix it.

- Winter months with lower water temperature and/or higher total dissolved solids (TDS) due to a change in water chemistry.

Water blob followed by a slow trickle from the faucet.

- Check for a ruptured tank bladder by attempting to fill air using a bicycle pump or air compressor. Only test the tank air pressure when it is water-free. If the tank is still functional, you will be able to charge and maintain 6 psi air. If not, replace both the tank and the tank ball valve.

Drain running continuoiusly.

- Tank not completely filled. Drain will run until the tank is filled.Extend the waiting time for the tank to fill. To simulate a full tank, shut the tank ball valve; within a few minutes, the drainage should cease. If it persists, there may be a malfunction in the auto shutoff valve.

- On electrical pump systems, if the tank is full and the drain keeps running, then the tank pressure sensor (high pressure switch) may be faulty.

- Check valve malfunction causing water leakage.

Filtered water TDS same as feed water.

- Membrane not correctly placed within the membrane housing.

- Incorrect connections. Reconfigure the RO system by consulting the tubing diagram.

Filtered water TDS higher than feed water.

- Mix-up in the placement of membrane housing drain (waste) and filtered water line (permeate).

Leak from the RO System

- Identify the source of the leak. If it's between the housing and a cap, apply lubrication to the o-ring.

- For leaks on quick connect fittings, remove the tubing, make a square cut, and reinsert the tubing.

- If hairline cracks are detected in pre-filter or membrane housings, replace both the housing and cap. Additionally, assess the inlet water pressure and install a pressure regulator on the feed line if it surpasses 75 PSI.

Excessive noise during tank filling due to vibrations.

- Secure tubing from the RO auto shutoff valve with zip ties to avoid contact between the tubing and copper pipes. Some vibrations in the tubing are normal during tank filling.

- Ensure that the reverse osmosis (RO) membrane element is correctly installed within the membrane housing. Failure to have a membrane in place can result in violent vibrations, particularly in RO systems equipped with pressure booster pumps.

Bad taste and/or odor from filtered water

- Sanitize the reverse osmosis (RO) system with Sani RO Cleaner and install new membranes and filter cartridges.

For concerns not covered here, please reach out to WECO for assistance.

References:

- Peck, S. (n.d.). REMOVING CHLORINE AND CHLORAMINES FROM MUNICIPAL TAP WATER. AXEON Water Technologies. Retrieved from http://www.axeonwater.com

- Reverse Osmosis System Components. (n.d.). ANAN Knowledge Base Administration. Retrieved from https://wqa.org.

- UNIVERSITY OF NEBRASKA–LINCOLN. (n.d.). Understanding Your Pressure Storage Tank. Retrieved from https://communityenvironment.unl.edu

Conversation 0 Comment(s)