Components of a Home RO Filter System

What are the main components of a residential reverse osmosis drinking water filter system?

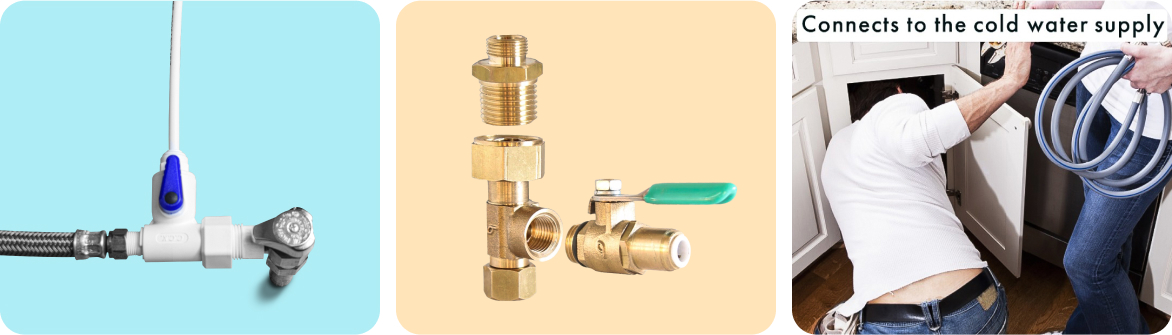

A water supply connector also known as a feed water supply adapter connects to the house cold water supply as the source of water to the reverse osmosis filter. WECO RO systems come with an adapter that fits both 1/2" and 3/8" supply valves. Your manufacturer may include a variety of fittings, valves, and saddle valves that are available to best match the plumbing configuration.

2. Pressure Regulator (optional)

A pressure regulating valve is used to protect the pre-filter housings from high pressure and water hammer. Standard housings typically have a maximum pressure rating of 75 PSI, especially in the case of clear housings made with Styrene Acrylonitrile (SAN) plastic.

The sediment cartridge removes sand, grit, precipitated mineral particles, insoluble iron oxide and other debris that can clog the reverse osmosis membrane surface or plug the drain flow restrictor, causing reduced water production. Most WECO ro systems use sediment filters rated to remove particulate matter down to 5 micron. We recommend replacing this filter at least every 6 months. TINY ro sedeiment filters need to be replaced every 3 months.

4. Carbon Filter for Chlorine Removal

Drinking water is disinfected by city utilities to prevent growth of harmful bacteria, viruses and other microorganisms that can cause searious illnesses and/or death. However, these chlorinated water supplies can deteriorate TFC membranes over time. Most city water utilities require water leaving the plant to have a minimum chlorine level of 1.0 mg/L (1.0 ppm). After 1000 ppm-hours of free chlorine exposure, the RO membranes may allow increased TDS passage (less contaminant rejection). The carbon filter removes chlorine and protects the membrane downstream of it.

5. Carbon Filter for Chloramine Removal

Water utilities like the Los Angeles Department of Water and Power (LADWP) recently started using chloramine to disinfect water. The new standard was by the US Environmental Protection Agency and the State was the result of numerous studies linking the chlorine disinfection by-products to a higher risk of cancer. Reverse Osmosis membranes are able to withstand a higher concentration of chloramines (1 to 2 ppm) versus chlorine (0.1 ppm) before damage to the membrane can lead to lower salt rejection. However, metals such as iron or aluminum in water can act as catalysts and accelerate the oxidation of membranes even at low concentrations of chloramines. Activated carbon is also effective against chloramine. However, since the amount of activated carbon required to provide sufficient contact time for effective chloramine removal is about 5 times that needed for chlorine, most WECO reverse osmosis systems are equipped with a 0.5 micron carbon filter specialy rated for chloramine reduction.

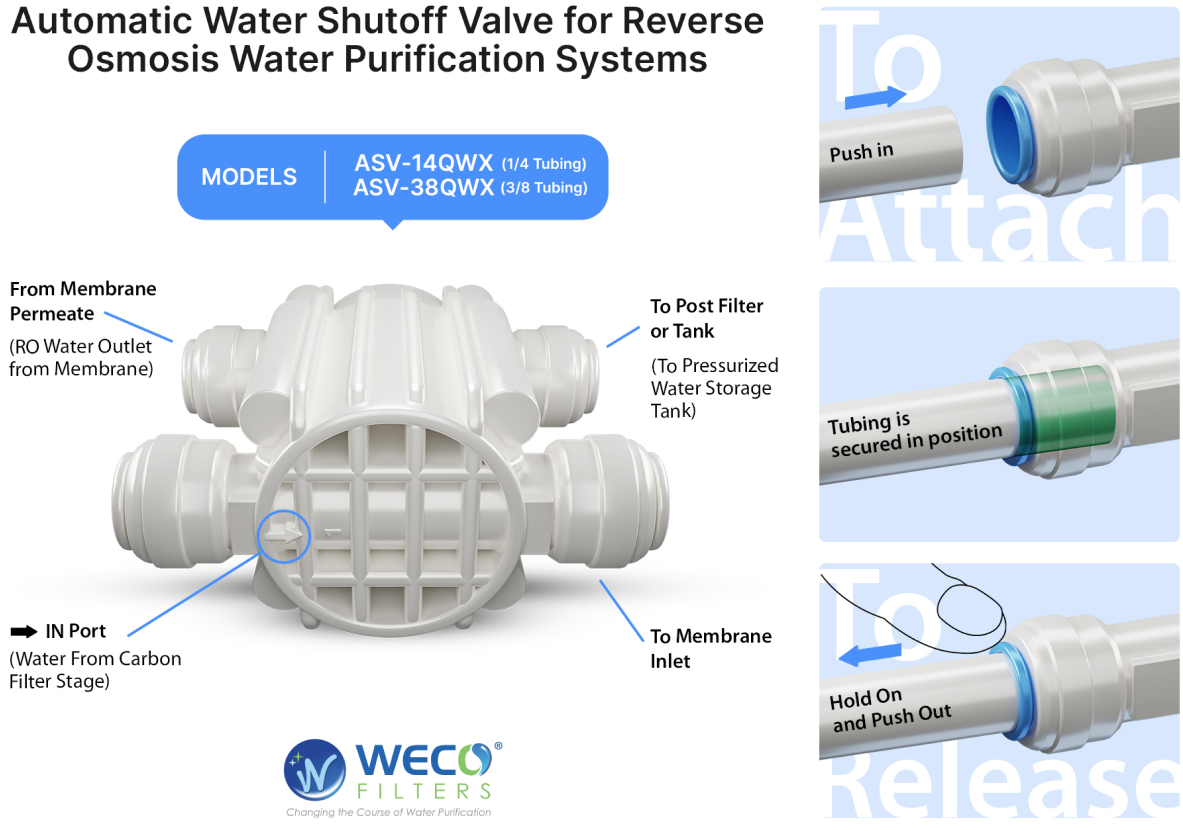

6. Auto Shut-off Valve (ASO Control Valve)

Conserves water by eliminating the drain flow when the tank is full. Main purpose of the ASO valve is to controls the water supply to the reverse osmosis membrane. When the pressurized storage tank fills 2/3 of the feed pressure, ASO valve cuts off the water supply to the membrane and waits until the tank is drained down to 1/3 of the feed pressure before turning water back on.

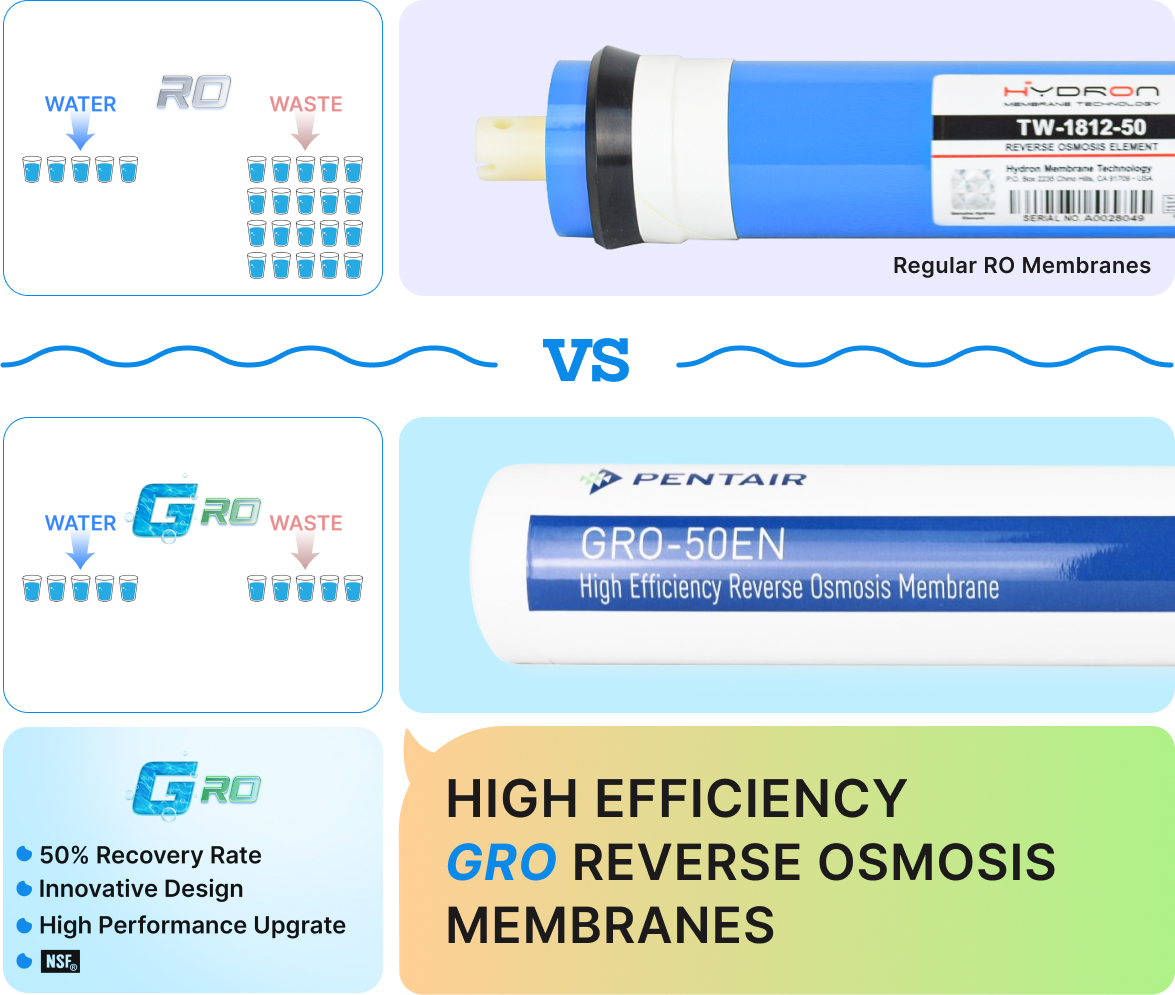

RO membrane does most of the heavy work in the system. It removes over 96% of total dissolved solids (i.e. salts, minerals, metals), microorganisms and organic substances in water. Membrane divides the water flow into two streams. Filtered water from the membrane goes to the storage tank. Reject water goes into the drain. Most standard RO systems produce around 4 gallons of waste water per 1 gallon purified (4:1) if you're on a city water supply above 70 PSI water pressure. This ratio is controlled by the flow restrictor on the drain line. WECO VGRO systems, CLARINA systems, VS-150 light commercial systems only waste 1 gallon for every gallon purified since they employ the water saving GRO membrane technology.

8. Check Valve

Check valve prevents pressurized filtered water in the storage tank from flowing back and rupturing the RO membrane when the ASO valve turns off the feed water pressure to the membrane. Our systems employ a check valve on the permeate (filtered water) line immediately after the membrane.

A granular activated carbon polishing filter removes any remaining tastes and odors in water. Since water flows very slowly through ths filter, the "contact time" is higher and this leads to higher adsorption effectiveness.

10. Pressurized Water Storage Tank

The pressure tank in a RO system stores filtered water from the membrane permeate and provides water under pressure when the drinking water faucet is turned on. A bladder within a metal or plastic case separates a water chamber from compressed air. When the tank fills up with RO water, the bladder expands and further compresses the air inside the casing. Opening the faucet causes the air under pressure to push the water out. Residential under sink RO water storage tanks typically has an empty tank air charge of 5-7 PSI. Increasing the air charge will reduce the volume of stored water. Lower empty tank air pressure in the tank will result in lower flow rate from the drinking water faucet.

12. Optional RO Components

References:

-

Peck, S. (n.d.). REMOVING CHLORINE AND CHLORAMINES FROM MUNICIPAL TAP WATER. AXEON Water Technologies. Retrieved from http://www.axeonwater.com

-

Reverse Osmosis System Components. (n.d.). ANAN Knowledge Base Administration. Retrieved from https://wqa.org.

-

UNIVERSITY OF NEBRASKA–LINCOLN. (n.d.). Understanding Your Pressure Storage Tank. Retrieved from https://communityenvironment.unl.edu

- Aquaguard Service Center