Backwash/Whole House Filter Questions & Answers

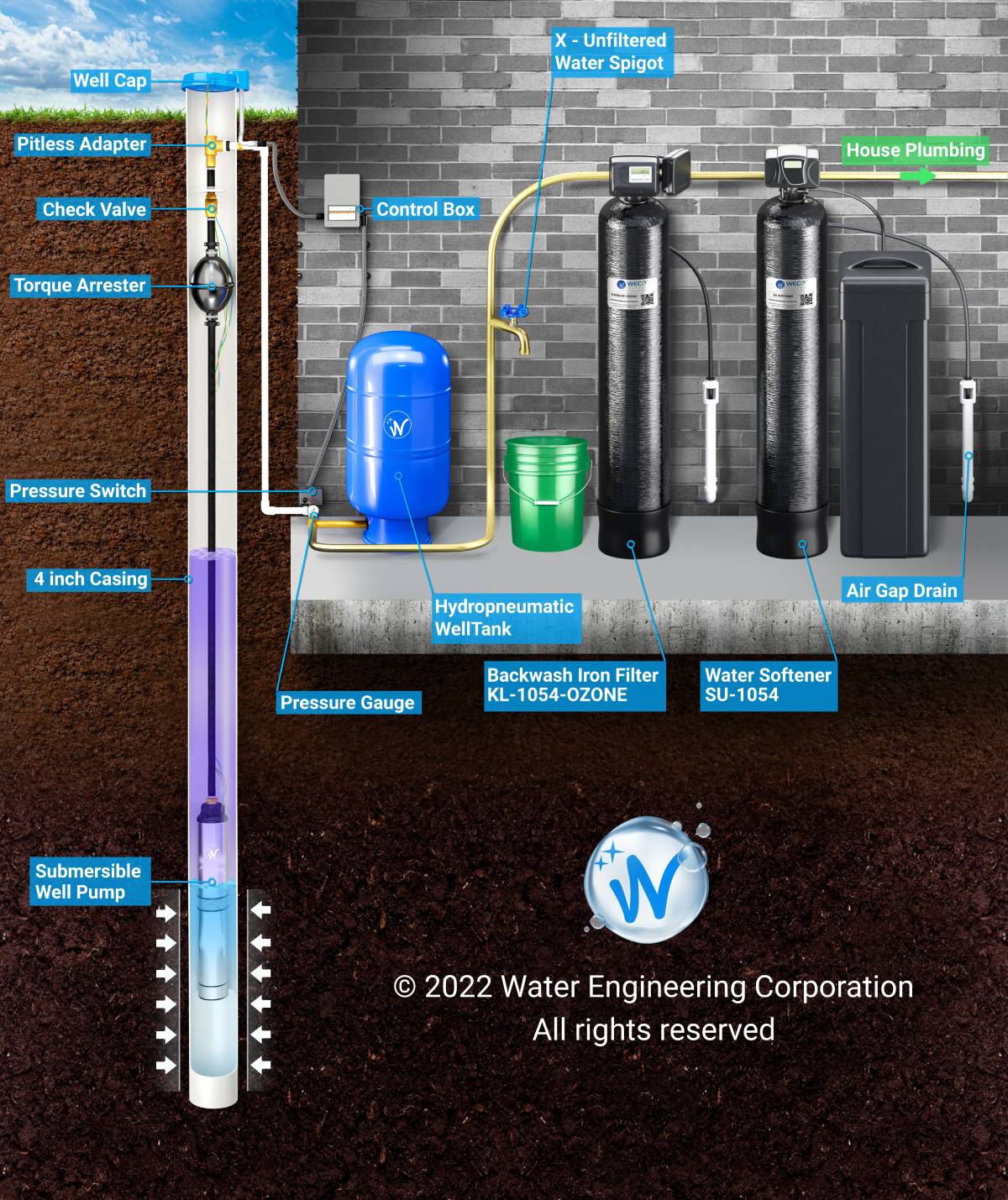

What is my available backwash flow rate?

Determine the available backwash flow rate.

Have a stopwatch and a utility bucket for measuring water volume (in gallons) ready.

Make sure to turn off all faucets, showers and water using appliances in the house.

Open X unfiltered water spigot and run water until well pump turns on. Close X spigot. Allow the well pump to build up pressure inside your hydropneumatic well tank and automatically shutoff when cutoff pressure is reached.

Open X spigot, run water into a 5 gallon utility bucket and measure how many Gallons drawn down from the tank turns the well pump back on. Close X immediately when pump comes on and time how many Seconds pump stays on.

How often should filters be backwashed?

As filtration proceeds, the void areas in the medium become filled with particles removed from the water, resulting in pressure drop from the outlet. Flow rates through the filter medium decreases until it becomes insufficient to meet the demand. A partially clogged filter bed also results in deteriorated water quality. Backwash systems must be programmed to backwash at a different time than other treatment equipment to lessen the potential for over running the drainage system.

One way to make the when-to-backwash decision is to install pressure gauges before and after the filter. Backwashing should be performed when the pressure drop reaches a pre-determined maximum value (typically 15 PSI for whole house systems). Backwash the system on demand by pressing the Regeneration button on the home screen. Manual Regeneration can only be used while the valve is in the treatment position.

Backwash lengths and frequencies vary by the application. Below are typical for residential whole house filter applications.

Municipal Applications

| Application | Media Used | Backwash Time |

|---|---|---|

| Chlorine Reduction | Granular Activated Carbon / Catalytic Carbon | every 14-28 days: 10-16 min per backwash |

| Sediment Reduction | NEXT Sand / Katalox Light | every 7-28 days: 10-16 min per backwash |

Well Applications

| Application | Media Used | Backwash Time |

|---|---|---|

| Iron/Chlorine Reduction | Granular Activated Carbon / Catalytic Carbon | every 14-28 days: 10-16 min per backwash |

| Sediment Reduction | NEXT Sand / Katalox Light | every 7-28 days: 10-16 min per backwash |

| Arsenic Reduction | Nano Titanium Oxide | every 14-21 days: 10 min per backwash |

| Iron Reduction | Katalox Light | every 14-28 days: 10-16 min per backwash |

| Iron Reduction | KDF-85 | every 3 days: 10-16 min per backwash |

| pH Neutralizing | Calcite / Magnesium Oxide | every 3-7 days: 10-16 min per backwash |

Please note that a minimum of 20 psi (1.4 bar) of water pressure is required for the backwash/regeneration valve to operate effectively. You must have an air gap on the drain line to prevent back flow of drain water into the system. A 2x the drain line pipe diameter air gap is required with a minimum 1" air gap.

How often should softeners be regenerated?

Once you test and enter the hardness level of water in your UXC softener control panel, the automated control valve decides when to regenerate based on the amount of water passed through the softener. Our softeners are programmed to 'Softener Delayed' regeneration type. This means that your softener measures water usage and regenerates the system at the selected Regeneration Time after the calculated system capacity is depleted. The control calculates the system capacity by dividing the unit capacity by the feed water hardness and subtracting the reserve.

The reserve should be set to ensure that the system delivers treated water between the time the system capacity is depleted and the actual regeneration time. Reserves can be set at a Fixed Volume, Fixed Percentage of capacity, a Variable Reserve based on the previous calendar day's water usage, or a Weekly Reserve based on the average water usage for the current day of the week. The default for the day override parameter is OFF, and the default reserve type is Weekly Reserve. A Softener Delayed control will also start a regeneration cycle at the selected Regeneration Time (2:00 AM default for softeners, 12:00 AM default for filters) if a number of days equal to the Day Override pass before water usage depletes the calculated system capacity. If the regen type is changed from Softener Immediate to Softener Delayed (or vice-versa), all parameters within those types will be reset to factory default.

What service flow velocities are possible?

Please vist the equipment web page for a service flow and backwash flow chart or contact a WECO support professional.

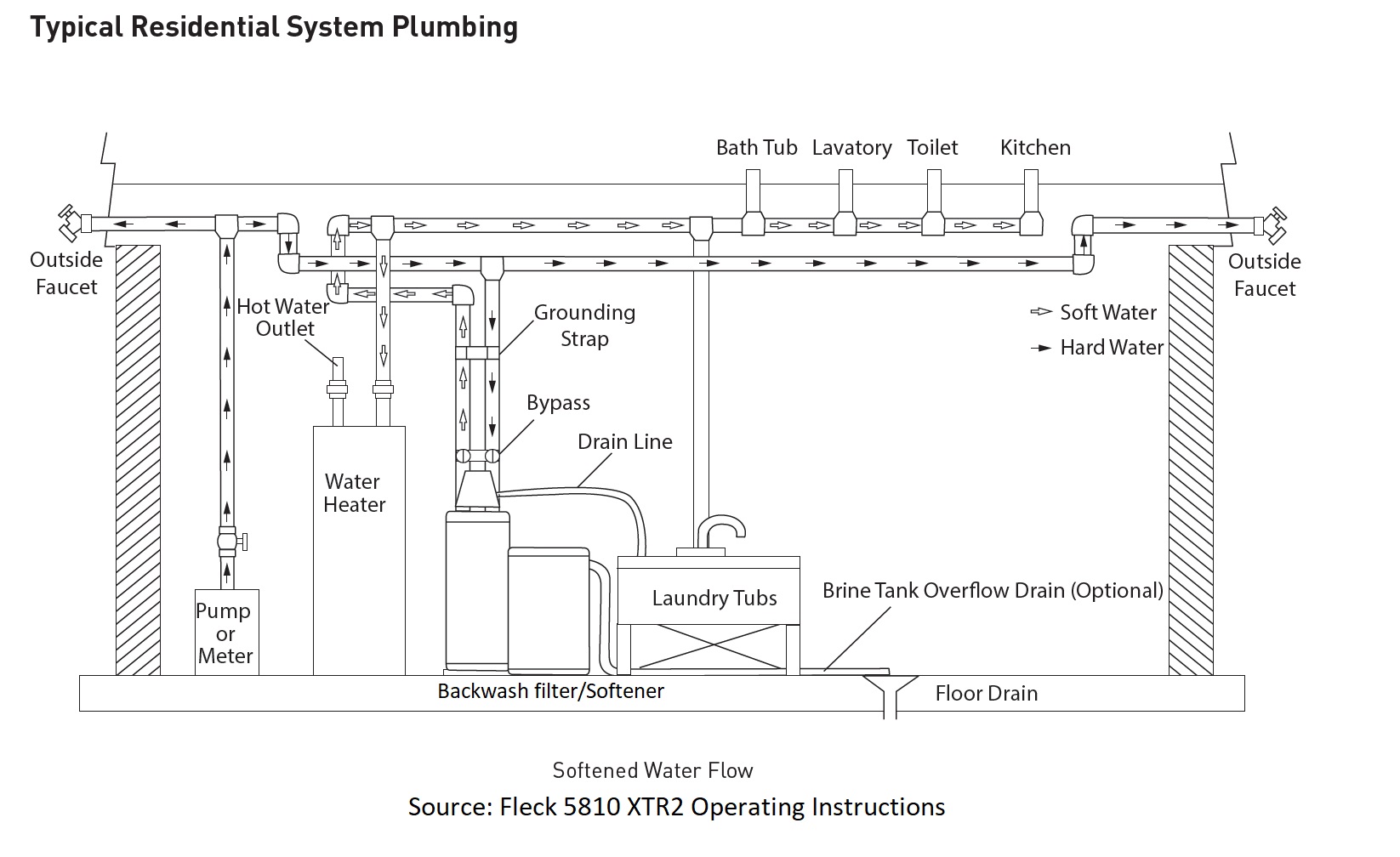

Where should a softener/backwash filter installed?

Make sure the installation location meets following requirements.

- Water pressure and flow rate are sufficient to support backwash/regeneration.

- There is an adequate drain for maximum total volume produced during the regeneration cycle and can be used with an air gap device per local plumbing codes.

- There is an electrical outlet to connect the control head transformer.

- Adequate space for installation.

When do I change filter media?

Media life will depend on the type of media used in your backwash filter, available backwash flow rate and the concentration of contaminants treated. NEXT sand is advertised to last 5 year or longer. Katalox light recommended media life is 7-10 years. Catalytic carbon backwash filters typically need media changed every 4-6 years. A water softener resin bed normally lasts 5 to 10 years. Life for nano titanium oxide media used for arsenic reduction is application specific contact us with a water analysis for recommended replacement frequencies.

How can I disinfect the filter/softener?

The materials of construction of the modern water softener will not support bacterial growth, nor will these materials contaminate a water supply. During normal use, a softener may become fouled with organic matter, or in some cases with bacteria from the water supply. This may result in an off-taste or odor in the water. Some softeners may need to be disinfected after installation and some softeners will require periodic disinfection during their normal life. Depending upon the conditions of use, the style of softener, the type of ion exchanger, and the disinfectant available, a choice can be made among the following methods.

Cut open one packet of 0.25 oz liquid sanitizer and pour down the brine well tube of the brine tank. Manually run the softener through a regeneration cycle.

Sodium or Calcium Hypochlorite

These materials are satisfactory for use with polystyrene resins, synthetic gel zeolite, greensand and bentonites.

5.25% Sodium Hypochlorite

These solutions are available under trade names such as Clorox*. If stronger solutions are used, such as those sold for commercial laundries, adjust the dosage accordingly.

1. Dosage

A. Polystyrene resin; 1.2 fluid ounce (35.5 ml) per cubic foot.

B. Non-resinous exchangers; 0.8 fluid ounce (23.7 ml) per

cubic foot.

2. Salt tank softeners

A. Backwash the softener and add the required amount of hypochlorite solution to the well of the salt tank. The salt tank should have water in it to permit the solution to be carried into the softener.

B. Proceed with the normal recharge.

*Clorox is a trademark of the Clorox Company.

Calcium Hypochlorite

Calcium hypochlorite, 70% available chlorine, is available in several forms including tablets and granules. These solid materials may be used directly without dissolving before use.

1. Dosage

A. Two grains (approximately 0.1 ounce [3 ml]) per cubic foot.

2. Salt tank softeners

A. Backwash the softener and add the required amount of hypochlorite to the well of the salt tank. The salt tank should have water in it to permit the chlorine solution to be carried into the softener.

B. Proceed with the normal recharge.

References:

- Fleck 5810 XTR2 Control Valve Service Manual

- “Troubleshooting Problems with POE Backwashing Tank Filtration Systems.” Water Quality Association, Knowledge Base Administration, www.wqa.org